Square energy storage battery pack design

Review on Battery Packing Design Strategies for Superior Thermal

In the last decades of electric vehicle (EV) development, battery thermal management has become one of the remaining issues that must be appropriately handled to ensure robust EV design. Starting from researching safer and more durable battery cells that can resist thermal exposure, battery packing design has also become important to avoid thermal

Battery Pack Design of Cylindrical Lithium-Ion Cells and

model for a prismatic lithium battery cell of high energy capacity based on experimental results. In terms of mechanical structure, the basic structure of a battery pack is determined by the

Trends in Automotive Battery Cell Design: A Statistical Analysis of

Searching for the best possible trade-off between energy and power capability nowadays also increasingly involves battery pack design and system optimization [3,4,14,18], such as optimized cell Reinhart, G.; Jossen, A. Multi-scale investigation of thickness changes in a commercial pouch type lithium-ion battery. J. Energy Storage 2016, 6

Utility-Scale Battery Storage | Electricity | 2022 | ATB | NREL

Current Year (2021): The 2021 cost breakdown for the 2022 ATB is based on (Ramasamy et al., 2021) and is in 2020$. Within the ATB Data spreadsheet, costs are separated into energy and power cost estimates, which allows capital costs to be constructed for durations other than 4 hours according to the following equation:. Total System Cost ($/kW) = Battery Pack Cost

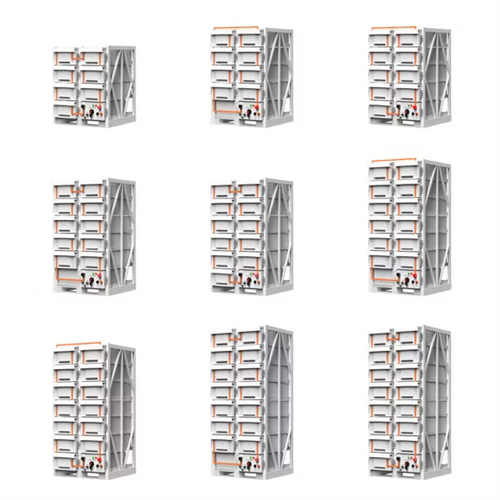

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Battery Energy Storage System (BESS) containers With an expansive factory covering approximately 300,000 square meters and employing around 1,000 skilled workers, we are well-equipped to meet the diverse (modular & fan-free design) Safe & Reliable • IP67 battery pack • Multi-level battery protection

Tesla Megapack

The Tesla Megapack is a large-scale rechargeable lithium-ion battery stationary energy storage product, intended for use at battery storage power stations, manufactured by Tesla Energy, the energy subsidiary of Tesla, Inc.. Launched in 2019, a Megapack can store up to 3.9 megawatt-hours (MWh) of electricity. Each Megapack is a container of similar size to an intermodal

The Handbook of Lithium-Ion

Battery Pack Design Chemistry, Components, Types and Terminology John Warner XALT Energy, Midland, MI, USA AMSTERDAM • BOSTON • HEIDELBERG • LONDON • NEW YORK • OXFORD Figure 24 Types of energy storage for grid scale units 202 Figure 25 A123 Grid Storage System™ 204

Utility-scale battery energy storage system (BESS)

Battery rack 6 UTILITY SCALE BATTERY ENERGY STORAGE SYSTEM (BESS) BESS DESIGN IEC - 4.0 MWH SYSTEM DESIGN Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind, due to their unique ability to absorb quickly, hold and then

Li-Batt Design App

One of the graphical user interface pages in the Li-Batt Design App Building better lithium-metal batteries. Through a simple, flexible interface the user can custom design a lithium metal battery based on available cathodes and cell accessories in the market. The user can also input a new cathode material with voltage and capacity information to generate mathematical solutions

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

• analyze the battery pack''s structure, system, installation status and use environment Pack Sizing Considering the ratings of the BMS and battery cell (5200mA maximum discharge rate), we calculate the number of cells in parallel. Table 3: battery pack size and nominal ratings BMS Model Discharge current (A) Pack configuration Nominal Ratings

A critical review of battery cell balancing techniques, optimal design

Another important aspect of EV energy storage optimization is optimal battery pack design. The selection of battery chemistry, cell arrangement, thermal management, and packaging is crucial in determining the overall efficiency and performance of the system. Topologies for converting energy between the cells to balance the battery pack are

A review on structure model and energy system design of

As traditional batteries cannot provide adequate energy density and power density, more and more vehicles are using lithium batteries because of its high working voltage (3 times of traditional battery) and high energy density (up to 165 Wh/kg, 5 times of traditional battery) [7], [8].Known as "green battery", lithium battery is able to remain stable under

Journal of Energy Storage

With the escalation of global energy crises and environmental pollution, governments worldwide are seeking immediate ways to reduce carbon emissions [1, 2] this context, the vigorous development of electric vehicles has gradually emerged as a global trend and a crucial means to promote emission reduction [[3], [4], [5]].Electric vehicles rely on clean

Thermal equalization design for the battery energy storage

Ultimately, six such arrays are combined to make up one battery pack. This method results in a lithium battery pack configuration of 189 batteries connected in series, totaling 48 groups and amounting to 9072 individual batteries. Detailed parameters of these energy storage units at each level are provided in Table 10.

The Handbook of Lithium-Ion Battery Pack Design

In addition to traditional engineering tools and processes used in battery development, many computer-aided engineering (CAE) software packages are being modified or are receiving add-in components to enable mechanical and thermal analyses of electrochemical battery cells and their related energy storage systems to reduce the design and

Handbook On Lithium Battery Pack Design

2 How to design a battery pack transportation, and energy-storage applications, even if they tend to be more expensive than equivalent battery technologies with aqueous electrolytes. Li-ion batteries are still in a relatively early phase of development in relation to the energy storage industry, and have only been readily available for 15

A Guide to Battery Energy Storage System Design

Read this short guide that will explore the details of battery energy storage system design, covering aspects from the fundamental components to advanced considerations for optimal performance and integration with renewable energy

Designing better batteries for electric vehicles

Those changes make it possible to shrink the overall battery considerably while maintaining its energy-storage capacity, thereby achieving a higher energy density. "Those features — enhanced safety and greater energy density — are probably the two most-often-touted advantages of a potential solid-state battery," says Huang.

Inside AC Block Architecture: A Technical Walkthrough

3 天之前· In this excerpt from the Foundations of BESS course, industry expert Drew Lebowitz examines the critical design elements of a 50MW/200MWh installation using an instructional scale model. Welcome to a tour of a scale

Everything You Should Know About an Energy Storage System (ESS)

Here are the main components of an energy storage system: Battery/energy storage cells – These contain the chemicals that store the energy and allow it to be discharged when needed. Battery management system (BMS) – Monitors and controls the performance of the battery cells. It monitors things like voltage, current and temperature of each cell.

Numerical investigation on thermal characteristics of a liquid

The average battery pack temperature remains in the desirable temperature range for a substantial duration (65 %) of discharge process with PCM assisted battery pack at 3C condition, while it is

LFP Battery Pack Combined Heat Dissipation Strategy Structural

To optimize the heat dissipation performance of the energy storage battery pack, this article conducts a simulation analysis of heat generation and heat conduction on 21 280Ah lithium

Design and optimization of lithium-ion battery as an efficient energy

The applications of lithium-ion batteries (LIBs) have been widespread including electric vehicles (EVs) and hybridelectric vehicles (HEVs) because of their lucrative characteristics such as high energy density, long cycle life, environmental friendliness, high power density, low self-discharge, and the absence of memory effect [[1], [2], [3]] addition, other features like

Modular battery design for reliable, flexible and multi-technology

The aim of this work is, therefore, to introduce a modular and hybrid system architecture allowing the combination of high power and high energy cells in a multi-technology system that was simulated and analyzed based on data from cell aging measurements and results from a developed conversion design vehicle (Audi R8) with a modular battery system

Effective Battery Design and Integration of Cylindrical Cells for

To fulfill the far-reaching requirements of an effective battery design for high power applications, every single component, including their interactions with the battery module, have to be optimized. energy storage performance assessment of repurposed 18650 cylindrical lithium-ion cells for second life application in battery energy storage

Switched supercapacitor based active cell balancing in lithium-ion

5 天之前· 2.2. Battery pack design. The battery pack is developed for modern-day two-wheeler EVs in this research work. The rating and size required for any EV depend on the load

Prognostics of the state of health for lithium-ion battery packs in

As an effective way to solve the problem of air pollution, lithium-ion batteries are widely used in electric vehicles (EVs) and energy storage systems (EESs) in the recent years [1] the real applications, several hundreds of battery cells are connected in series to form a battery pack in order to meet the voltage and power requirements [2].The aging of battery cells

Understanding pouch battery

Pouch lithium-ion battery is a liquid lithium-ion battery covered with a polymer shell. The biggest difference from other batteries is the soft packaging material (aluminum-plastic composite film), which is also the most critical and technically difficult material in pouch lithium-ion battery pack.. Pouch packaging materials are usually divided into three layers, namely the outer barrier layer

Tesla Megapack

The Tesla Megapack is a large-scale rechargeable lithium-ion battery stationary energy storage product, intended for use at battery storage power stations, manufactured by Tesla Energy, the energy subsidiary of Tesla, Inc.. Launched

Design approach for electric vehicle battery packs based on

Fuzzy Least Square Support Machine Vector model for SoC estimation. 50 Ah LiFePO 4 prismatic battery cell this work presents a multi-domain modelling approach for the design and sizing of new energy storage system (ESS) configurations for EVs, taking into account experimental electro-thermal data at a single cell level for a given BP layout

Related Contents

- Energy storage battery pack knowledge ppt

- Energy storage container battery pack picture

- Energy storage battery pack assembly

- Energy storage battery pack hoisting

- Lithium battery energy storage pack manufacturer

- Energy storage cabinet battery pack composition

- Energy storage battery management system design

- Design of energy storage lithium battery system

- New energy storage battery design solution

- Battery energy storage system design courseware

- Energy storage polymer lithium iron battery pack

- Energy storage battery scene design