Energy storage battery copper foil usage

Solid-state lithium-ion battery: The key components enhance the

A widening of Li-ion battery usage depends on the type of SSBs with low weight and volume, superior energy production, trouble-free Li ions transmission, and enhanced efficacy [10], [14]. On the other hand, Solid-state batteries have a unique advantage over other energy storage devices and capacitors [15], [16] .

Composite current collector

High specific energy: Under the same conditions, the energy density is expected to increase by more than 5%. Composite current collectors, especially composite copper foils, can achieve significant weight reduction. According to the data,

Journal of Energy Storage

Further investigation into the relationship between degradation and cycle number during the energy storage battery usage phase is necessary. To simplify calculations, this paper utilizes an empirical formula derived from previous studies to determine energy loss per cycle. The environmental problems of battery copper foil production are

Preparing ultra-thin copper foil as current collector for improving

Adopting ultra-thin copper foil as the current collector is one of the most important strategies for improving the gravimetric energy density of lithium-ion batteries (LIBs), however,

Lithium and water: Hydrosocial impacts across the life cycle of energy

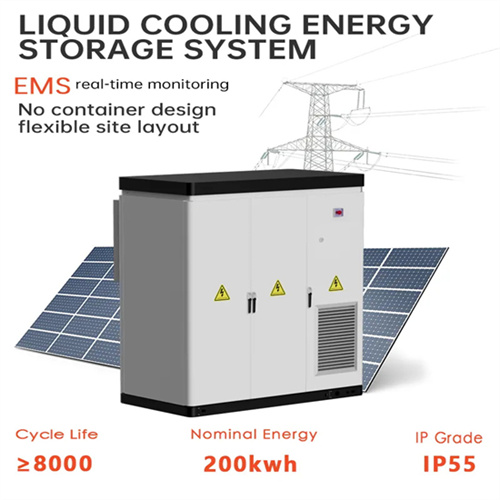

Batteries have allowed for increased use of solar and wind power, but the rebound effects of new energy storage technologies are transforming landscapes (Reimers et al., 2021; Turley et al., 2022). Some stationary battery energy storage systems use active cooling water systems for thermal management (Li et al., 2018; Siruvuri & Budarapu, 2020

Battery Foil: The Unsung Hero of Energy Storage Solutions

2. Renewable Energy Storage. Efficient energy storage solutions are essential for integrating renewable energy sources like solar and wind into the power grid. High-performance battery foils enable the development of large-scale energy storage systems that can store and deliver renewable energy reliably and cost-effectively.

Phenomenal Growth in Energy Storage

Energy storage—battery technology in particular—is often seen as having great potential to decarbonise power and transport systems. Recent cost reduction of Li-ion batteries has raised Copper foil is normally used at a thickness of around 10 microns. This guarantees both a satisfying electronic conductivity and

New Energy Battery Packs Copper Busbar

We supply directly to many battery pack companies and energy storage companies like solar energy household storage projects in UK, Americal, Australia etc. offering solutions for their battery connecting. They use both flexible and solid copper busbar to meet different design and application requirments.

Aluminum, Copper & Nickel Foil for Batteries

We supply battery-grade aluminum, copper and nickel alloy foils for lithium-ion, nickel cadmium and nickel metal hydride battery cell manufacturers. strict quality management practices with innovative handling techniques to ensure we consistently receive the best copper foil for battery manufacturing. We specialize in converting and

Copper Foil Market Trends

The rising demand for electric vehicles and energy storage will surge the consumption of copper foils in the region. In addition, regulations on carbon emissions, combined with the initiatives by the European Union to achieve a circular economy by 2030, will support the regional market growth. (VES) is constructing a new copper foil battery

The Role of Copper Foil in Next-Generation Battery

Copper foil promises a bright future in shaping our energy landscape through more efficient and eco-friendly battery technologies. Through continuous innovations that bring forth new opportunities while addressing current

Growing Nanostructured CuO on Copper Foil via Chemical

Metallic lithium is one of the most promising anode materials to build next generation electrochemical power sources such as Li-air, Li-sulfur, and solid-state lithium batteries. The implementation of rechargeable Li-based batteries is plagued by issues including dendrites, pulverization, and an unstable solid electrolyte interface (SEI). Herein, we report the use of

Aluminum Foil for Cell & Capacitor Manufacturers

Aluminum has been extensively used in recent years as a cathode foil in the manufacturing of lithium-ion batteries. Notable applications include consumer electronics and power tools, to Hybrid and Electric Vehicles. Our product line includes high-purity etched Al foil and battery-grade foils made from various alloys (1235, 1070, 1100, 1060).

Exploring the Role of Copper Battery Foil in Advanced Batteries

Why is Copper Battery Foil used in Batteries. Copper battery foil is commonly used in batteries for several reasons: 1. High Electrical Conductivity: Copper''s superior electrical conductivity ensures efficient electron flow, reducing energy loss and improving battery efficiency. 2.

The Critical Role of Copper Foil in Electric Vehicle Batteries

High-quality copper foil contributes to longer battery life by maintaining its structural integrity over numerous charge-discharge cycles. Top-tier EV batteries can now achieve over 1,000 cycles

Battery Grade Copper Foil Market Size, Growth and Forecast

The use of battery grade copper foil helps in improving the overall performance and efficiency of lithium-ion batteries. In energy storage cells, copper foil aids in enhancing the capacity and

Hindalco plans expansion into copper foil to tap into growing

Hindalco plans expansion into copper foil to tap into growing market for EVs, energy storage The latest foray comes as the Aditya-Birla flagship company aims at capitalizing on the accelerating

First copper foil production plant in Europe to boost EV battery

Unlike other materials used for battery production which are scarce and climate aggressive, copper foil is an underutilised – material that has a high conductivity of electricity and heat. The use of copper foils in EV batteries is expected to contribute to the achievement of the Green Deal, EU Taxonomy and Fit for 55 climate action goals

Preparing ultra-thin copper foil as current collector for improving

Adopting ultra-thin copper foil as the current collector for LIBs is one of those supplementary strategies for enhancing the battery performances [15].The average weight ratio of 8 µm copper foil current collector in the commercial LIBs is high up to 2.8 % [16] creasing the thickness of copper foil can lighten the weight of the LIBs while remaining the energy capacity

A Deep Dive into Copper Foil and EV Battery Efficiency

Why Copper Foil is the Ideal Choice for EV Batteries. Copper foil is extensively used in the lithium-ion batteries that power electric vehicles, and for good reason: High Electrical Conductivity: Copper''s exceptional conductivity ensures efficient electron flow, maximizing battery performance and enabling faster charging.

Aluminum Air Battery

3 天之前· Show the students the materials they will be using to build the aluminum air battery (e.g., aluminum foil, copper foil, etc.) and have them guess the roles of each material in the battery cell. (See student worksheet A sustainable and low cost material for energy storage by Deepti Ahuja, Varshney Kalpna, and Pradeep K Varshney 2021 J

The Role of Copper Foil in Next-Generation Battery

From powering electric vehicles to revolutionizing renewable energy storage systems, copper foil has quietly changed how we access and store energy. In this blog post, we''ll investigate copper foil''s current application to battery

What is the role of copper foil in lithium battery?

According to the application field, it can be divided into lithium copper foil and standard copper foil. The thickness of lithium copper foil is generally less than 20m, which is an important raw material for manufacturing lithium batteries. Widely used in automotive power lithium battery, 3C digital products, energy storage and other fields.

The Science Behind Copper Foil and Battery Performance

Powering Performance. Conductivity is Key: Copper''s exceptional conductivity allows more power to flow through the battery, boosting its overall performance and enabling faster charging and

Are Na-ion batteries nearing the energy storage tipping point

Here, battery energy storage systems (BESS) play a significant role in renewable energy implementation for balanced power generation and consumption. Another cost reduction would come from the exchange of copper foil for aluminum foil for the anode current collector in the SIBs because sodium does not form an alloy at low potential with

Copper Foil Substrate Enables Planar Indium Plating for Ultrahigh

When copper foil is used, an indiophilic indium‐copper alloy interface can be formed in situ upon plating, exhibiting favorable binding energies and low diffusion energy barriers for indium atoms. Consequently, a planar, smooth, and dense indium metal layer is uniformly deposited on the copper substrate, leading to outstanding plating

What We Can Expect Copper Foil On EV Battery Industry In The

Flexible Energy Storage Materials: Future power batteries might employ thin-film battery technology, especially in applications requiring lightweight and flexibility, such as flexible

Sustainability in Copper Foil Manufacturing

Energy Efficiency and Renewable Energy Integration. Another key area of focus is energy efficiency. Copper foil production is energy-intensive, but manufacturers are now investing in energy-efficient machinery and technologies. For instance, the use of advanced furnaces and electrolysis equipment can significantly cut down on energy consumption.

Copper Foil Flexible Storage Energy Battery Busbar

Flexible busbar is make of T2 copper foil, which is 99.9% copper contented. It capitals the products excellect conductivity with less impurities. Laminated copper busbar have more current carrying surface area. The surface of flexible busbar can be bare or plated to protect copper busbar from oxidation or creating aerugo.

Global Lithium Battery Copper Foil Market

Lithium Battery Copper Foil Latest Research Report. Complete Market Research, Market Analysis, CAGR, Trends, Major Players, Market Share, Market Size. - by Type (Electrolytic Copper Foil, Rolled Copper Foil), By Application (Automotive, Consumer Electronics, Industrial, Energy Storage, Medical Devices), By Thickness (Below 10 µm, 10-20

Aluminum Foil for Cell & Capacitor Manufacturers

Aluminum has been extensively used in recent years as a cathode foil in the manufacturing of lithium-ion batteries. Notable applications include consumer electronics and power tools, to Hybrid and Electric Vehicles. Our product line

Tuning intrinsic lithiophilicity of copper foil to improve

Therefore, for a sustainable future of energy storage devices, research on anode-free lithium metal batteries (AFLMBs) should be at the forefront. Ltd.), battery grade rolled-annealed copper foil (RA-Cu), carbon coated aluminum foil, LiNi 0.8 Co 0.1 Mn 0.1 O 2 powder and liquid electrolytes: 1 M LiDFOB in EC/DMC (1:1

Composite current collector

High specific energy: Under the same conditions, the energy density is expected to increase by more than 5%. Composite current collectors, especially composite copper foils, can achieve significant weight reduction. According to the data, traditional copper foil accounts for about 13% of the total weight of lithium batteries, which is a key material that affects the quality and

Battery Aluminum Foil Materials for Lithium-ion Cell | HDM

HDM is the leading supplier of battery foil materials for lithium-ion energy storage technology in the Asia-Pacific region. With the support and cooperation of domestic and international experts and battery manufacturers, we select the ideal alloys, roll them with high precision, and manufacture them in a clean environment.

6 FAQs about [Energy storage battery copper foil usage]

Can copper foil be used as a current collector for lithium ion batteries?

Adopting ultra-thin copper foil as the current collector for LIBs is one of those supplementary strategies for enhancing the battery performances . The average weight ratio of 8 µm copper foil current collector in the commercial LIBs is high up to 2.8 % .

What is lithium copper foil?

According to the application field, it can be divided into lithium copper foil and standard copper foil. The thickness of lithium copper foil is generally less than 20m, which is an important raw material for manufacturing lithium batteries. Widely used in automotive power lithium battery, 3C digital products, energy storage and other fields.

What is electrolytic copper foil?

Electrolytic copper foil is the key functional basic raw material of electronic manufacturing industry, mainly used to manufacture lithium ion battery and printed circuit board (PCB). According to the application field, it can be divided into lithium copper foil and standard copper foil.

Can ultra-thin copper foil be used as a current collector?

Adopting ultra-thin copper foil as the current collector is one of the most important strategies for improving the gravimetric energy density of lithium-ion batteries (LIBs), however, stumbled by the quality-control of physicochemical properties for ultra-thin foils.

What are the advantages of copper foil?

Copper foil has good electrical conductivity, good flexibility, moderate potential, winding resistance, mature manufacturing process and relatively low price.

How a copper foil current collector is used for LIBS?

Currently, copper foil used for LIBs is dominantly prepared by continuous electrodeposition in the sulfate electrolyte , , . The initial thickness of copper foil current collector for LIBs is high up to 12 µm, which is gradually replaced by 6 µm.

Related Contents

- Copper busbar usage in energy storage industry

- Cairo special energy storage battery usage

- Does new energy storage require copper foil

- Mobile energy storage backup battery

- Energy storage battery production site video

- Photovoltaic energy storage battery price trend

- Malabo steel battery energy storage container

- Outdoor portable energy storage battery outdoor

- North asia energy storage battery brand

- 80a energy storage battery

- Energy storage battery magnesium

- Portable energy storage battery shipments