Extrusion process storage modulus

Preparation and Characterization of Glass-Fiber-Reinforced

The storage modulus was maintained in the glassy state and can indicate the stiffness of the materials. The storage modulus was increased with increasing GF content. This trend is similar to the results of the flexural modulus in Figure 4. As the temperature increased, the storage modulus began to drop in the glass transition region where the

Effects of mixing temperature on the extrusion rheological

1 Introduction Extrusion is a common approach in polymer processing. 1–3 In particular, a variety of rubber products, such as tire treads/sidewalls, 4–6 seal strips, 7,8 wires 9 and hoses 10,11 are obtained by the extrusion process. Rubber is a type of viscoelastic material, which means it exhibits both viscous and elastic characteristics when undergoing deformation.

Complex modulus increase as a function of storage time for

Download scientific diagram | Complex modulus increase as a function of storage time for double-base propellants from publication: Optimization of extrusion process of double-base propellants from

A systematic printability study of direct ink writing towards high

During the DIW pneumatic extrusion process, non-Newtonian fluid is extruded from the micro-nozzle by shear thinning and deposited as a customized pattern under the motion of the print substrate The storage modulus increase with increasing SE1700 content in the hybrid ink, and the and for Newtonian fluid pure Sylgard184 ink are constant.

Physicochemical Changes and Resistant-Starch Content of

The storage modulus, G'', is a measure of the amount of energy stored in materials and recovered during cycling, which is indicative of the solid or elastic characteristic of the materials. This finding show that the extrusion process combined with storage at low temperature is a viable alternative for RS production, through an environment

Preparation and Characterization of Glass-Fiber

The storage modulus was maintained in the glassy state and can indicate the stiffness of the materials. The storage modulus was increased with increasing GF content. This trend is similar to the results of the flexural

Extrusion 3D Printing of Polymeric Materials with

Advincula and co-workers have demonstrated that the incorporation of salt gel in the ink could transform the liquid like PDMS resin (loss modulus > storage modulus) into a thixotropic gel-like ink (storage modulus > loss modulus).

Process fundamentals and quality investigation in extrusion 3D

The storage modulus is the response to the elasticity and mechanical strength of the material system, which represents the internal stress during the recovery process and the energy stored by the elastic deformation, while the loss modulus corresponds to the viscosity characteristics of the system, which represents the energy dissipated in the

Multilayer 3D bioprinting and complex mechanical properties of

We measured the time-dependent shear storage modulus G'', shear loss modulus G", complex viscosity ({eta }^{*}), and loss tangent tan (δ) by time sweeps (oscillation). All rheological

3D Printing Ceramics—Materials for Direct Extrusion Process

Additive manufacturing and 3D printing methods based on the extrusion of material have become very popular in recent years. There are many methods of printing ceramics, but the direct extrusion method gives the largest range of sizes of printed objects and enables scaling of processes also in large-scale applications. Additionally, the application of this method to

Essential Guide to Hydrogel Rheology in Extrusion 3D Printing:

The viscoelastic behaviour of a fluid is characterised by two primary functions: the elastic or storage modulus (G′), which represents the energy accumulated by the material

A reduced-order model of thermo-viscoelastic filaments in a

High-resolution and high-efficiency simulations are a great challenge in a material extrusion process. This paper developed a reduced-order thermo-viscoelastic model based on discrete differential geometry. [52], and Cristea [53], the storage modulus can be high up to 3 GPa as the material turns to be solid, which currently poses a big

Melt Extrusion

The hot melt extrusion method was established in the early 1930s, since then, it has rapidly become the most widely used processing method in the plastic, rubber, and food manufacturing industries [27].Extrusion is the process used to change the physical properties of the raw materials by pushing them through a die of the desired cross section under elevated controlled

Performance enhancement of PEBAX using supercritical fluid extrusion

The results showed that the tensile modulus at 50% elongation amongst three different scenarios was not significantly different, but that the tensile modulus at 100% and 300% and also the final

Rheological properties of cross-linked hyaluronic acid dermal

DF in the manufacturing process, characterized by a dy-namic, double cross-linking process yielding cohesive mono-phasic HA gel (26). In Table II the DF rheological properties, in terms of the elastic and viscous modulus, tanδ, the complex rigid-ity modulus and viscosity of all samples at a frequency of 0.1 Hz are listed.

Extrusion Processing and Properties of Protein‐Based

Current literature concerning extrusion of proteins revealed that successful processing is only possible within a small window of operating conditions. Extrusion uses thermal and mechanical energy to form a polymer

Material extrusion of electrochemical energy storage devices for

Rheological properties of inks play a significant role in determining printability, extrusion process, strength of printed filament, and post-treatment requirement. (G″) indicates the viscous part of inks, which is lost due to friction during ink flow. On the other hand, the storage modulus (G′) is the amount of elastic energy stored in

3D printing of low carbon steel using novel slurry feedstock

The damping factor was calculated by dividing loss modulus with storage modulus. The storage modulus amplitude increased from 1.91× 10 7 Pa to 4.03 × 10 7 Pa when the metal content increased from 35 vol% to 45 vol% (Fig. 3 (d)). The storage modulus amplitude increased from 1.22 × 10 7 Pa to 5.66 × 10 7 Pa when the binder concentration

A review on material extrusion (MEX) of polyethylene

Additionally, it is crucial for the polymer melt to be dominated by an elastic behavior, where the ratio of the loss modulus to the storage modulus (G"/G'') is less than unity, while also possessing a high yield stress (σ y) to prevent post-extrusion cracking of the extrudate. Additionally, it is essential to ensure the fast alternation

Extrusion-Based 3D Food Printing: Technological Approaches

In the screw-based extrusion process, recommended ingredients are mixing separately and feed to the cartridge and materials moved with the help of a screw tube and passed through the nozzle tip. The various rheological properties like storage modulus (G′), loss modulus (G″), Complex modulus (G*), loss tangent, yield stress flow stress

Investigation into the effects of fillers in polymer processing

The increase of storage modulus of polymer-based PNCs in comparison to the neat polymer is due to the higher modulus of the nanoparticle which suggests a reinforcing effect and improves the thermo-mechanical stability of the matrix. Moreover, the increase in storage modulus indicates the rise of the stiffness of PNCs [29]. Clearly, the elastic

Introduction to Dynamic Mechanical Analysis and its Application

The storage modulus G'' and tan δ were measured at a frequency of 1 Hz and a strain of 0,07% at temperatures from -120 °C to 130 °C. In Figure 7, the DMA traces of nylon fibers made from moist and pre-dried pellets in an extrusion process are shown. The elastic modulus of the moist pellets has a higher value above the glass transition

High elastic modulus polyethylene: Process-structure

extrusion process using hydrostatic extrusion and draw-ing.11 Various HDPE products were produced using this technique having moduli ranging between 20 and 25 GPa. Another reported technique using a solvent-free approach to obtain HDPE products with a high modulus is the roller-drawing method, as reported by Nakayam

Investigation of the effect of materials and processing conditions

The granules obtained from the extrusion process were added (3–4 g) to the preheated cylinder of the injection molding machine. Once the material melted, the gate was sealed, and the injection process was started. The average storage modulus and average loss modulus of PMMA increased with increasing screw speed and decreased with

3D Printing Ceramics—Materials for Direct Extrusion

Additive manufacturing and 3D printing methods based on the extrusion of material have become very popular in recent years. There are many methods of printing ceramics, but the direct extrusion method gives the largest range of

Extrusion

In this process the storage modulus of the jammed microgels increased from 25 to 130 Pa upon silver coordination. Interestingly, the conductivity of the jammed microgels (0.05 S cm −1 ) was significantly larger than in bulk (0.01 S cm −1 ) or compared to milled hydrogel pieces (0.028 S cm −1 ) due to the overall higher silver content in

Optimizing process conditions and ensuring end product

Figure 6 the strand came out of the extrusion line as an even strand with no signs of surface defects. Figure 5: Storage modulus G'', loss modulus G'''' and the complex viscosity Iη*I as a function of the angular frequency ω for a polystyrene melt at 190°C. Figure 6: Storage modulus G'' as a function of the angular frequency ω

Protein blend extrusion: Crafting meat analogues with varied

The storage modulus (G'') and loss modulus (G") depict elasticity and viscosity during material deformation. Energy storage and loss modulus curves (Fig. 1 A) reveal that values for each protein mixture rise with oscillation frequency.

Physicochemical Changes and Resistant-Starch

The best yield of RS obtained in the EAS was 1.134 g/100 g, corresponding to an increase of 68% compared to native starch. This finding show that the extrusion process combined with storage at low temperature is

Related Contents

- Energy storage cell extrusion test

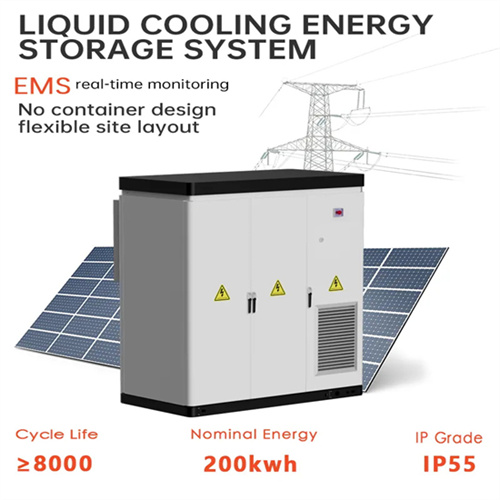

- Energy storage box manufacturing process

- Energy storage product procurement process design

- Grid-side energy storage grid connection process

- Working process of energy storage container

- Blk222 energy storage process

- Home energy storage production process

- Energy storage container inspection process

- Energy storage container assembly line process

- Australian energy storage project export process

- Sao tome energy storage silver plating process

- Flexural modulus and storage modulus